Joint Usage / Research Center

Summary and Call for Proposals

Image of Shared Use

-

Research teams including researchers from other institutes/universities and IMaSS

Researchers from other

institutes/universities

(Research representative)

Researchers from IMaSS

▼

Joint research by utilizing the facilities, equipments, data, and other items of IMaSS.

Wide range of research from fundamental research on advanced materials and devices to

systems for their social implementations.

▼Realization of the development of environment-friendly and sustainable energy-saving and energy-creating technologies

(energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption).

Summary and Call for Proposals

Joint Usage/Research Center of energy-friendly and sustainable energy-saving and energy-creating materials and systems research

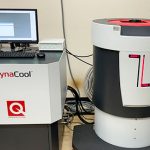

IMaSS has been newly certified as a "Joint Usage/Research Center of energy-friendly and sustainable energysaving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology for 6 years from FY2022, and it is aimed at realizing the development of environmentfriendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers. At this facility, researchers from universities, research institutions and other organizations based in Japan and abroad can engage in joint research together with IMaSS personnel while utilizing a wide range of equipment including film-deposition systems, micro/nanofabrication equipment, electron microscopes and many other types of analysis instruments.

If you wish to apply for joint usage or research at this facility, please consult the IMaSS staff in advance and apply.

Call for “IMaSS joint usage/joint research program” in FY2026 Application Deadline: January 15, 2026 (Thursday) Reports Deadline: March 1, 2027 (Monday)

The Institute of Materials and Systems for Sustainability, Nagoya University (hereinafter referred to as IMaSS) was established on October 1, 2015 by reorganizing the Ecotopia Science Institute which was the only science and engineering institute attached to Nagoya University. The purpose of establishing this institute is to contribute to the realization of an environment-friendly and sustainable society by engaging in research on new materials and systems.

Since 2016, IMaSS had been certified as a joint usage/joint research center of materials and systems for innovative energy management by the Ministry of Education, Culture, Sports, Science and Technology. To realize innovative energy management (involving energy creation/conversion, storage, transmission, advanced consumption, and ultraefficiency), the center has consistently taken a bird's-eye view from basic research on elemental technologies, such as cutting-edge materials and devices to system technologies, for social implementation and has been promoting the development of innovative energy management technology through joint usage/joint research with domestic and overseas researchers.

From FY2022, the center has been newly certified as a "Center of joint usage/joint research on energy-friendly and sustainable energy-saving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology, and it is aimed at realizing the development of environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers.

As part of the activities of this center, the development, joint usage, and joint research of environment-friendly and sustainable energy-saving and energy-creating technologies are carried out in cooperation with faculty members belonging to IMaSS.

| Joint usage/joint research | A research team including faculty members of this institute and faculty members or researchers belonging to institutions other than this institute (for the research team, refer to "2. Qualified applicants") uses, among others, the facilities, equipment, and data of this institute. |

|---|---|

| Joint usage/joint research subject | Joint usage/joint research on environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). |

| Qualified applicant | Principal Investigator (PI) PI must meet one of the following requirements. (i) Researcher belonging to national, public or private university or research institute, or similar researcher; (ii) Researcher approved by the director of IMaSS. Co-investigator (Co-I) Co-I must meet one of the following requirements; (i) Researchers belonging to national, public or private university or research institute, or similar researcher; (ii) Technical staff and graduate student; (iii) Researcher approved by the director of IMaSS. |

| Research period | The research period is from the date of adoption until the end of February 2027. Applications for the continuation of the same research project can be made up to three times, including the first application. |

| Application procedure/Submission address/Miscellaneous | Please refer to the "Application Guideline (PDF)" below. |

| Application Submission deadline | January 15, 2026 (Thursday) |

| The deadline for submitting research reports | March 1, 2027 (Monday) |

Call for “IMaSS joint usage/joint research program (international collaboration)” in FY2026-2028

Application Deadline: January 15, 2026 (Thursday) Reports Deadline: March 1, 2029 (Thursday)

Institute of Materials and Systems for Sustainability, Nagoya University (hereinafter referred to as IMaSS) was established on October 1, 2015 by reorganizing the Ecotopia Science Institute, which was the only science and engineering institute attached to Nagoya University. The purpose of establishing this institute is to contribute to the realization of an environment-friendly and sustainable society by engaging in research on new materials and systems.

Since 2016, IMaSS had been certified as a joint usage/joint research center of materials and systems for innovative energy management by the Ministry of Education, Culture, Sports, Science and Technology. To realize innovative energy management (involving energy creation/conversion, storage, transmission, advanced consumption, and ultraefficiency), the center has consistently taken a bird's-eye view from basic research on elemental technologies, such as cutting-edge materials and devices to system technologies, for social implementation and has been promoting the development of innovative energy management technology through joint usage/joint research with domestic and overseas researchers.

From FY2022, the center has been newly certified as a center of "joint usage/joint research on energy-friendly and sustainable energy-saving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology, and it is aimed at realizing the development of environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption).To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers.

As part of the activities of the center, the center calls for research proposals joint usage/joint research※ for the development of environment-friendly and sustainable energy-saving and energy-creating technologies, to be carried out in cooperation with faculty members belonging to IMaSS.

| Joint usage/joint research | Joint usage/joint research is research conducted jointly by research teams including faculty members of IMaSS and outside of IMaSS, using,among other, the facilities, equipment, and data of IMaSS. |

|---|---|

| Joint usage/joint research subject | Joint usage/joint research on environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). |

| Project Members | In this international joint research, the project members must include at least one researcher based overseas as the principal investigator or co-researcher. Additionally, the project members must include at least one IMaSS staff member as the corresponding researcher in IMaSS. Please have sufficient discussions in advance with the corresponding researcher in IMaSS regarding the research subject, contents, and expenditure, etc. The principal investigator and co-investigator must meet one of the following requirements (excluding faculty members of NU): (i) researcher belonging to national, public or private university or research institute, or similar researcher; (ii) researcher belonging to overseas research institute (including emeritus professor and postdoc, holding a doctoral degree); (iii) researchers approved by the director of IMaSS. |

| Research period | The research period is three years from the date of adoption until the end of February 2029. |

| Application procedure/Submission address/Miscellaneous | Please refer to the "Application Guideline (PDF)" below. |

| Application Submission deadline | January 15, 2026 (Thursday) |

| The deadline for submitting research reports | March 1, 2029 (Thursday) |

Call for “IMaSS joint usage/joint research program” in FY2025

Application Deadline: January 15, 2025 (Wednesday) *Application Registration is now closed. Reports Deadline: March 2, 2026 (Monday)

The Institute of Materials and Systems for Sustainability, Nagoya University (hereinafter referred to as IMaSS) was established on October 1, 2015 by reorganizing the Ecotopia Science Institute which was the only science and engineering institute attached to Nagoya University. The purpose of establishing this institute is to contribute to the realization of an environment-friendly and sustainable society by engaging in research on new materials and systems.

Since 2016, IMaSS had been certified as a joint usage/joint research center of materials and systems for innovative energy management by the Ministry of Education, Culture, Sports, Science and Technology. To realize innovative energy management (involving energy creation/conversion, storage, transmission, advanced consumption, and ultraefficiency), the center has consistently taken a bird's-eye view from basic research on elemental technologies, such as cutting-edge materials and devices to system technologies, for social implementation and has been promoting the development of innovative energy management technology through joint usage/joint research with domestic and overseas researchers.

From FY2022, the center has been newly certified as a "Center of joint usage/joint research on energy-friendly and sustainable energy-saving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology, and it is aimed at realizing the development of environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers.

As part of the activities of this center, the development, joint usage, and joint research of environment-friendly and sustainable energy-saving and energy-creating technologies are carried out in cooperation with faculty members belonging to IMaSS.

| Joint usage/joint research | A research team including faculty members of this institute and faculty members or researchers belonging to institutions other than this institute (for the research team, refer to "2. Qualified applicants") uses, among others, the facilities, equipment, and data of this institute. |

|---|---|

| Joint usage/joint research subject | Joint usage/joint research on environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). |

| Qualified applicant | Principal Investigator (PI) PI must meet one of the following requirements. (i) Researcher belonging to national, public or private university or research institute, or similar researcher; (ii) Researcher approved by the director of IMaSS. Co-investigator (Co-I) Co-I must meet one of the following requirements; (i) Researchers belonging to national, public or private university or research institute, or similar researcher; (ii) Technical staff and graduate student; (iii) Researcher approved by the director of IMaSS. |

| Research period | The research period is from the date of adoption until the end of February 2026. Applications for the continuation of the same research project can be made up to three times, including the first application. |

| Application procedure/Submission address/Miscellaneous | Please refer to the "Application Guideline (PDF)" below. |

| Application Submission deadline | January 15, 2025 (Wednesday) |

| The deadline for submitting research reports | March 2, 2026 (Monday) |

Call for “IMaSS joint usage/joint research program (international collaboration)” in FY2025

Application Deadline: January 15, 2025 (Wednesday) *Application Registration is now closed. Reports Deadline: March 1, 2027 (Monday)

Institute of Materials and Systems for Sustainability, Nagoya University (hereinafter referred to as IMaSS) was established on October 1, 2015 by reorganizing the Ecotopia Science Institute, which was the only science and engineering institute attached to Nagoya University. The purpose of establishing this institute is to contribute to the realization of an environment-friendly and sustainable society by engaging in research on new materials and systems.

Since 2016, IMaSS had been certified as a joint usage/joint research center of materials and systems for innovative energy management by the Ministry of Education, Culture, Sports, Science and Technology. To realize innovative energy management (involving energy creation/conversion, storage, transmission, advanced consumption, and ultraefficiency), the center has consistently taken a bird's-eye view from basic research on elemental technologies, such as cutting-edge materials and devices to system technologies, for social implementation and has been promoting the development of innovative energy management technology through joint usage/joint research with domestic and overseas researchers.

From FY2022, the center has been newly certified as a center of "joint usage/joint research on energy-friendly and sustainable energy-saving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology, and it is aimed at realizing the development of environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption).To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers.

As part of the activities of the center, the center calls for research proposals joint usage/joint research※ for the development of environment-friendly and sustainable energy-saving and energy-creating technologies, to be carried out in cooperation with faculty members belonging to IMaSS.

| Joint usage/joint research | Joint usage/joint research is research conducted jointly by research teams including faculty members of IMaSS and outside of IMaSS, using,among other, the facilities, equipment, and data of IMaSS. |

|---|---|

| Joint usage/joint research subject | Joint usage/joint research on environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). |

| Project Members | In this international joint research, the project members must include at least one researcher based overseas as the principal investigator or co-researcher. Additionally, the project members must include at least one IMaSS staff member as the corresponding researcher in IMaSS. Please have sufficient discussions in advance with the corresponding researcher in IMaSS regarding the research subject, contents, and expenditure, etc. The principal investigator and co-investigator must meet one of the following requirements (excluding faculty members of NU): (i) researcher belonging to national, public or private university or research institute, or similar researcher; (ii) researcher belonging to overseas research institute (including emeritus professor and postdoc, holding a doctoral degree); (iii) researchers approved by the director of IMaSS. |

| Research period | The research period is two years from the date of adoption until the end of February 2027. However, the research period for continuing applications will be one year. |

| Application procedure/Submission address/Miscellaneous | Please refer to the "Application Guideline (PDF)" below. |

| Application Submission deadline | January 15, 2025 (Wednesday) |

| The deadline for submitting research reports | March 1, 2027 (Monday) |

Call for “IMaSS joint usage/joint research program (international collaboration)” in FY2024

Application Deadline: January 15, 2024 (Monday) *Application Registration is now closed. Reports Deadline: March 2, 2026 (Monday)

Institute of Materials and Systems for Sustainability, Nagoya University (hereinafter referred to as IMaSS) was established on October 1, 2015 by reorganizing the Ecotopia Science Institute, which was the only science and engineering institute attached to Nagoya University. The purpose of establishing this institute is to contribute to the realization of an environment-friendly and sustainable society by engaging in research on new materials and systems.

Since 2016, IMaSS had been certified as a joint usage/joint research center of materials and systems for innovative energy management by the Ministry of Education, Culture, Sports, Science and Technology. To realize innovative energy management (involving energy creation/conversion, storage, transmission, advanced consumption, and ultraefficiency), the center has consistently taken a bird's-eye view from basic research on elemental technologies, such as cutting-edge materials and devices to system technologies, for social implementation and has been promoting the development of innovative energy management technology through joint usage/joint research with domestic and overseas researchers.

From FY2022, the center has been newly certified as a center of "joint usage/joint research on energy-friendly and sustainable energy-saving and energy-creating materials and systems research" by the Ministry of Education, Culture, Sports, Science and Technology, and it is aimed at realizing the development of environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption).To realize the development of energy-saving and energy-creating technologies, the center further promotes energy-saving and energy-creating technologies through joint usage/joint research by domestic and oversea researchers.

As part of the activities of the center, the center calls for research proposals joint usage/joint research※ for the development of environment-friendly and sustainable energy-saving and energy-creating technologies, to be carried out in cooperation with faculty members belonging to IMaSS.

| Joint usage/joint research | Joint usage/joint research is research conducted jointly by research teams including faculty members of IMaSS and outside of IMaSS, using,among other, the facilities, equipment, and data of IMaSS. |

|---|---|

| Joint usage/joint research subject | Joint usage/joint research on environment-friendly and sustainable energy-saving and energy-creating technologies (energy conversion, energy storage, energy transmission, and sophisticated and ultraefficient energy consumption). |

| Project Members | In this international joint research, the project members must include at least one researcher based overseas as the principal investigator or co-researcher. Additionally, the project members must include at least one IMaSS staff member as the corresponding researcher in IMaSS. Please have sufficient discussions in advance with the corresponding researcher in IMaSS regarding the research subject, contents, and expenditure, etc. The principal investigator and co-investigator must meet one of the following requirements (excluding faculty members of NU): (i) researcher belonging to national, public or private university or research institute, or similar researcher; (ii) researcher belonging to overseas research institute (including emeritus professor and postdoc, holding a doctoral degree); (iii) researchers approved by the director of IMaSS. |

| Research period | The research period is two years from the date of adoption to February 28, 2026 (Saturday). However, the research period for continuing applications will be one year. |

| Application procedure/Submission address/Miscellaneous | Please refer to the "Application Guideline (PDF)" below. |

| Application Submission deadline | January 15, 2024 (Monday) |

| The deadline for submitting research reports | March 2, 2026 (Monday) |

Facilities and Equipment

Coating Equipment

Microfabrication/Processing Device

Electronic Microscope & Associated Equipment

Analysis Measurement Equipment

Center for Integrated Research of Future Electronics / Center for Integrated Research of Future Electronics, Transformative Electronics Facilities

Please remove the '*'s before/after the @ sign when sending e-mails.